CNCTRAX Report

Machine Overview

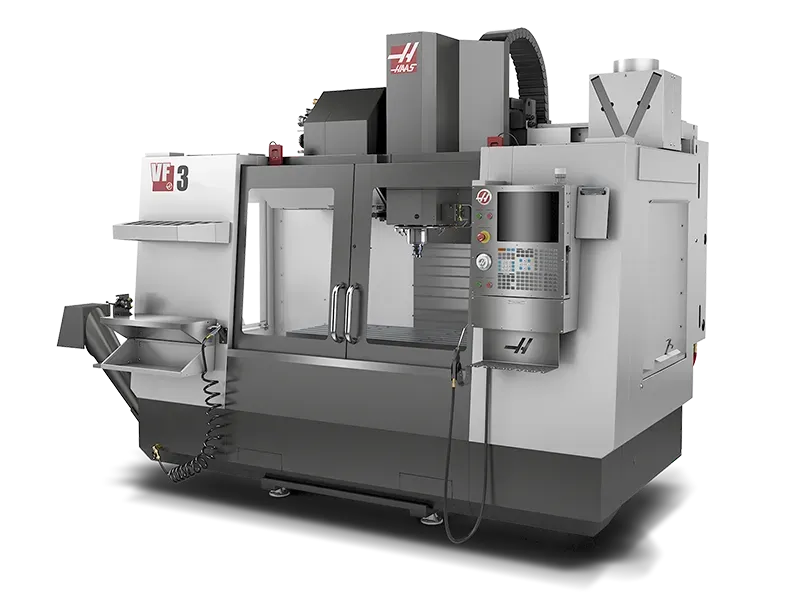

Brand:

Haas Automation

Model:

VF-3

Serial Number:

3087654

Year of Manufacture:

2018

Current Location & Usage History

Location:

Scottsdale, Arizona

Total Runtime Hours:

8,750 Hours

Previous Owners:

Contact us for more ownership information

Machine Specifications

This 2018 Haas VF-3 is a high-performance vertical machining center designed for precision and efficiency. It features a 12,000 RPM spindle, a 40+1 tool magazine, and a 40" x 20" x 25" work envelope, making it ideal for aerospace, automotive, and general machining applications.

Key Specifications include:

- Spindle Power: 30 HP (22.4 kW)

- Table Size: 48" x 18"

- Max Table Load: 3,500 lbs

- Control System: Haas NextGen CNC Control

- Machine Weight: 12,500 lbs

- Work Envelope: 121” x 118” x 122”

Upgrades & Add-Ons

- Through-Spindle Coolant (TSC): 300 PSI high-pressure system for deep-hole drilling

- Probing System: Haas Wireless Intuitive Probing (WIPS) for accurate tool and workpiece measurement

- Chip Conveyor: Standard Haas Conveyor System for efficient chip removal

- Programmable Coolant Nozzle: Allows precise coolant direction control

- Rigid Tapping: Enabled for improved thread machining

- High-Speed Machining Mode: Activated for faster cycle times

- 4th-Axis Ready: Pre-wired for rotary table integration

Maintenance & Parts Replaced

This Haas VF-3 has undergone regular preventative maintenance to ensure optimal performance.

Recent Maintenance & Service History:

- June 2023: Routine maintenance, spindle check, and coolant flush

- December 2022: Spindle bearing replacement, tool changer alignment

- August 2022: Coolant system inspection, chip conveyor maintenance

- March 2022: Lubrication system check, ball screw inspection

Parts Replaced:

- Spindle Bearings – Replaced in December 2022

- Coolant Pump – Replaced in August 2022

- Tool Changer Motor – Serviced in March 2022

Inspection Notes

Last Mechanical Health & Precision Check: June 2023

This machine is in good operational condition with no critical faults. The coolant system is functioning properly with no leaks, and the spindle runs smoothly with minimal vibration.

Potential Issues Identified:

- Minor signs of wear on X-axis ball screw but does not affect precision.

- Possible future replacement of way covers recommended.

Recommended Repairs & Next Service:

- Monitor X-axis backlash for signs of progression.

This machine has had no major crashes or collisions recorded during its lifespan and is a strong candidate for continued production or retrofit upgrades.

Compliance

Standards Met:

ISO 9001, AS9100

Last Calibration Date:

06/2023

Inspection Verified:

Yes

Machine Photos & Videos

Explore detailed images & Videos to see this machine in action

Additional Notes & Recommendations

- Machine has been used primarily for aluminum and stainless steel machining with moderate workloads.

- No major crashes or collisions recorded during its lifespan.

- Good candidate for continued production or retrofit upgrades for automation.

*This report has been generated as part of CNCTRAX’s commitment to professional CNC machine maintenance tracking and performance optimization.